Third Party Pharma Manufacturing

The pharmaceutical industry is growing quickly, and one of the major shifts we see today is the rise of third party pharma manufacturing. Instead of investing huge amounts of money in building factories and managing large teams, many pharma companies now choose to work with pharmaceutical manufacturing companies that handle production on their behalf.

This model, also called pharmaceutical contract manufacturing, is becoming popular because it allows businesses to focus on their strengths, such as marketing, sales, and research, while trained experts take care of the actual medicine production.

In simple terms, outsourcing production saves time, reduces costs, and ensures better quality because the work is managed by professionals who already follow strict industry standards.

What is Third Party Pharma Manufacturing?

Third party pharma manufacturing, often called contract manufacturing, is simply the process of outsourcing medicine production to a professional pharmaceutical manufacturing company. Instead of running their own factories, pharma brands partner with companies that already have the right setup, skilled staff, and certifications like GMP (Good Manufacturing Practices). This ensures every medicine is made safely, consistently, and with strict quality checks.

For growing pharmaceutical businesses, this model brings clear benefits:

- No need to spend crores on building infrastructure

- Products can reach the market much faster

- A dependable supply chain without the headache of managing production

- Freedom to focus more on branding, marketing, and expanding sales

Because of these advantages, many Pharma Franchise Companies today prefer outsourcing. It helps them save money, reduce risk, and stay competitive while still delivering high-quality medicines.

Understanding Pharmaceutical Manufacturing

Pharmaceutical manufacturing involves several key steps that ensure safe, effective medicines. Here’s how it works, step-by-step:

- Formulation development: Deciding on the dosage and ingredients for each medicine.

- Pharmaceutical production: Manufacturing products like tablets, capsules, syrups, and injectables.

- Quality control and assurance: Testing every batch to guarantee safety and meet international standards.

- Packaging and labelling: Making sure each medicine is correctly identified and prepared for distribution.

- Regulatory documentation: Completing the necessary paperwork so products comply with health regulations in India and abroad.

Why GMP is Important in the Pharmaceutical Industry

Good Manufacturing Practice (GMP) is the starting point of every pharmaceutical company in the manufacturing industry. These guidelines also ensure every single medicine produced and manufactured is safe, effective, and of high quality. For any drug manufacturing company, following GMP is not optional; it’s a core requirement.

Some of the key elements of GMP include:

- Regular checks and strict quality audits

- Active and engaged employee training

- Proper medical facilities and preemptive healthcare

- Structured manual and automated monitoring systems

For third party pharma manufacturers, GMP compliance is one of the core competencies a new client looks for. Meeting GMP compliance demonstrates the value of the company’s commitment to quality, credibility, and reliability in the market.

Advantages of Third Party Pharma Manufacturing

A third party manufacturing pharma company offers numerous advantages for pharmaceutical brands. Some of the more prominent benefits include:

- Cost Efficiency – Plant setup and expensive equipment purchasing are not necessary.

- Scalability – Production can easily be increased or decreased to align with market demands.

- Expertise – Access to advanced technology, skilled professionals, and established manufacturing processes.

- Time Efficiency – Infrastructure is pre-established, allowing for products to be launched considerably faster.

- Private Label Agreements – Provides the ability to market and sell medicines under the company’s brand, eliminating the need to run in-house production.

Instead of losing time and resources, this model allows companies to focus on branding and growth while skilled professionals handle manufacturing.

Private Label Pharmaceuticals

A growing trend in the market is private label pharmaceuticals. This allows businesses to sell medicines under their own branding while outsourcing production. For startups or smaller pharma firms, private labelling provides a quick entry into the market without large investment.

Benefits include:

- Stronger brand identity.

- Freedom to expand product portfolio.

- Flexible production options.

Role of Pharma Machinery Manufacturers

Behind every successful medicine manufacturing company are reliable pharma machinery manufacturers. From tablet compression machines to liquid filling systems and sterile packaging lines, advanced equipment plays a vital role in ensuring efficiency and precision.

While contract manufacturers invest in these machines, pharma brands benefit from the advanced technology without directly buying the equipment themselves.

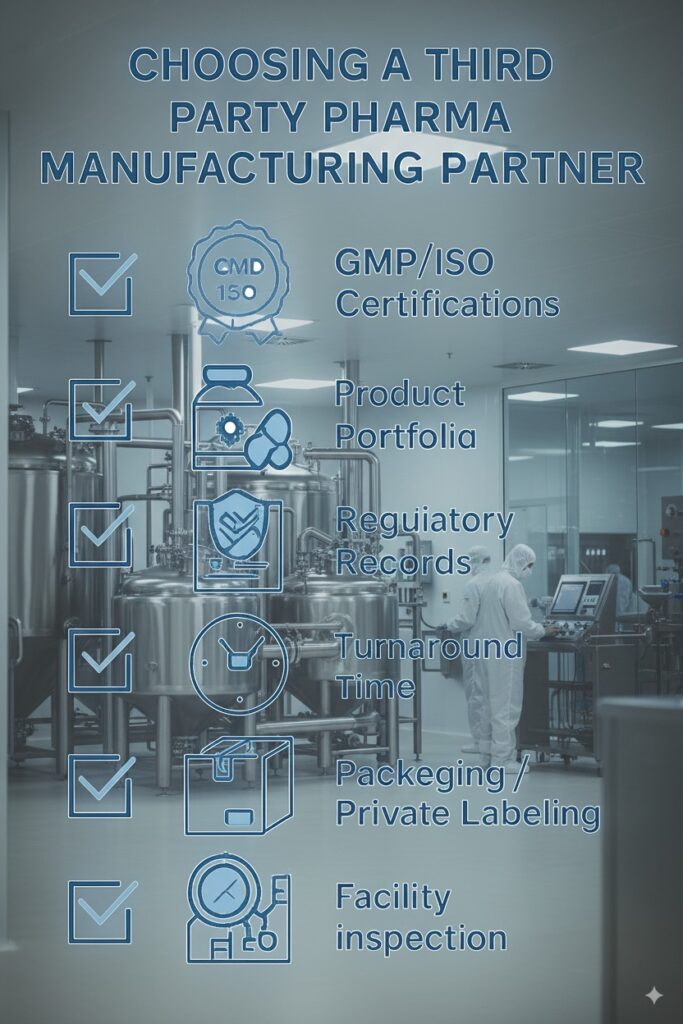

How to Choose the Right Third Party Pharma Manufacturing Partner

If you’re planning to outsource, here’s a quick checklist:

- Verify GMP and ISO certifications.

- Check product portfolio and batch sizes.

- Review regulatory compliance records.

- Ask about turnaround times and scalability.

- Evaluate packaging and private labelling capabilities.

- Inspect the facility or request virtual tours.

A reliable pharma manufacturing company will be transparent, responsive, and consistent in quality.

Conclusion

The trend of outsourcing pharma manufacturing has gradually become the backbone of contemporary pharmaceutical production. From drug manufacturing companies to pharma manufacturing outsourcing offers scalability, streamlined operations, and accelerated time to market.

Partnering with a reputable contractor that observes pharmaceutical industry standards like GMP helps companies to maintain quality standards while focusing on innovation and branding. If you are considering private label pharmaceuticals or are in search of long-term contract manufacturing, meaningful collaboration can change everything for your business.

Frequently Asked Questions (FAQ)

1) What is third party pharma manufacturing?

It is the outsourcing of the production of medicines to third party specialised pharmaceutical manufacturing companies. Such companies operate under GMP guidelines and handle formulation, production, and even packaging.

2) What are the benefits of third party manufacturing in pharma?

Access to specialised production facilities, expert human capital, branding, marketing, and distribution, while costing less and saving time.

3) What is GMP in the pharmaceutical industry?

Good Manufacturing Practices define the strict quality guidelines to be followed in the production of medicines and their supervision, so that they are produced uniformly and under control.

4) How do I choose the best third party pharma manufacturing company?

Ensure that they have GMP and ISO certification, a strong product portfolio, a reliable supply chain, adherence to regulations, and transparency, among other non-GMP and ISO certified competitors.

5) What are private label pharmaceuticals?

Private label pharmaceuticals are products produced by one company and sold to another under a different brand name. It allows businesses to expand rapidly because they do not need to set up a manufacturing unit.

One thought on “Third Party Pharma Manufacturing”

Comments are closed.